Boost production line efficiency with top-quality industrial printing machines that are engineered for reliability, precision, and consistent performance across demanding production environments.

Industrial printing machines are an essential component of modern production lines, supporting businesses that rely on high-volume, accurate, and consistent print output. Businesses looking to scale operations often aim to find industrial printing machines for your needs that align with their production goals and technical requirements.From packaging and labelling to textiles and manufacturing, these machines help streamline operations while maintaining strict quality standards. By automating complex printing tasks, they reduce manual intervention, minimise errors, and support faster turnaround times.

The Role of Industrial Printing Machines in Production

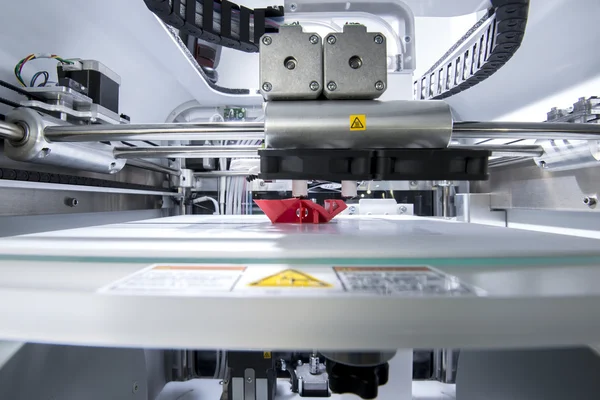

Industrial printing machines are designed to handle large-scale printing tasks with precision and speed. They operate using advanced printing methods such as digital, offset, and flexographic processes, depending on the application. These systems manage ink flow, material feeding, and alignment automatically, ensuring consistent results even during extended production runs.

Across various industries, industrial printing machines are used to produce packaging materials, product labels, textiles, circuit markings, and customised designs. Their ability to deliver uniform output at high volumes makes them indispensable in sectors where branding accuracy and compliance are critical. By integrating seamlessly into production lines, they support efficient workflows and reduce bottlenecks.

High-quality industrial printing equipment directly impacts productivity by minimising downtime and maintenance issues. Reliable machines operate at higher speeds while maintaining clarity and colour accuracy, allowing businesses to meet tight deadlines without compromising quality. This combination of speed and consistency leads to improved operational efficiency and better use of resources.

Overview of Top-Quality Industrial Printing Machines

Top-quality industrial printing machines are defined by their durability, precision, and adaptability to different production needs. These machines are built to perform consistently in demanding environments, handling continuous workloads without sacrificing print quality.

Advanced features often include high-resolution output, automated calibration, and compatibility with a wide range of materials. These capabilities allow manufacturers to adapt quickly to changing production requirements while maintaining efficiency. The benefits extend beyond output quality, as modern machines are also designed to optimise energy usage and reduce material waste.

Recent technological developments have further enhanced industrial printing systems. Innovations such as automation, intelligent monitoring, and improved control interfaces enable operators to manage production more effectively. These advancements help reduce errors, improve workflow visibility, and ensure consistent performance across multiple shifts.

How Industrial Printing Machines Enhance Efficiency

High-quality industrial printing machines significantly improve efficiency throughout the production line. Their precision reduces the likelihood of reprints and material wastage, while automated processes limit the need for manual adjustments. This leads to smoother operations and more predictable output levels.

Modern machinery also supports faster setup times and quicker transitions between jobs. By reducing downtime and simplifying maintenance procedures, businesses can maximise production capacity and meet increasing demand. Improved reliability allows teams to focus on optimisation rather than troubleshooting, contributing to overall operational effectiveness.

Real-world examples across manufacturing sectors demonstrate measurable gains in efficiency after upgrading to advanced industrial printing machines. Many operations report increased output, reduced error rates, and lower long-term costs, highlighting the value of investing in reliable and well-engineered equipment.

Factors to Consider When Purchasing Industrial Printing Machines

Choosing the right industrial printing machine requires careful consideration of business size, production volume, and application requirements. Smaller operations may prioritise flexibility and ease of use, while large-scale manufacturers often require high-speed systems capable of continuous operation.

Efficiency, durability, and technology are key factors that influence long-term performance. Machines built with robust components and modern printing technology tend to offer greater reliability and lower maintenance demands. Cost should be evaluated not only in terms of initial investment but also ongoing operational expenses and lifespan value.

After-sales support and warranty coverage are equally important considerations. Reliable technical assistance and comprehensive warranties help protect investments and ensure minimal disruption to production. Strong support services contribute to long-term satisfaction and help businesses maintain consistent output levels over time.

Impact of Technological Advancements on Industrial Printing Machines

Technological innovation continues to drive improvements in industrial printing machines, resulting in higher quality, faster speeds, and greater versatility. Advancements in automation and intelligent control systems allow machines to self-monitor performance and maintain optimal settings throughout production.

Emerging trends in industrial printing include increased use of artificial intelligence, data-driven optimisation, and environmentally conscious design. These developments support more efficient operations while addressing sustainability goals. As technology evolves, industrial printing machines are becoming more adaptable, enabling businesses to respond quickly to market changes and customisation demands.

Future manufacturing environments are expected to rely heavily on smart printing systems that integrate seamlessly with digital production workflows. These innovations will further enhance efficiency, reduce costs, and improve overall print quality across industries.

Conclusion

Top-quality industrial printing machines play a crucial role in enhancing production line efficiency by delivering consistent, high-quality output at scale. Their ability to streamline processes, reduce downtime, and support automated workflows makes them an essential investment for modern manufacturing environments.

Businesses that invest in high-quality industrial printing machines benefit from improved productivity, reliable performance, and long-term cost savings. By adopting advanced printing technology, organisations can strengthen their operational capabilities, maintain high standards, and remain competitive in an increasingly demanding marketplace.